The HCT (Hollow Cyli nder Torsional) device subjects a relatively thin, long hollow cylindrical specimen to a combination of axial and torsional stresses, in addition to fluid pressures on the inside and outside cylindrical surfaces.

nder Torsional) device subjects a relatively thin, long hollow cylindrical specimen to a combination of axial and torsional stresses, in addition to fluid pressures on the inside and outside cylindrical surfaces.

The HCT device is the only device that permits a soil specimen to be subjected to multi-axial loading with controlled variations in the magnitudes of the three principle stresses and the direction of the major principle stress with the vertical sample deposition direction.

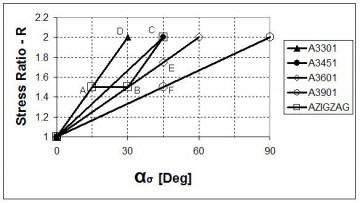

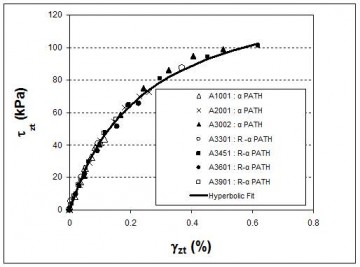

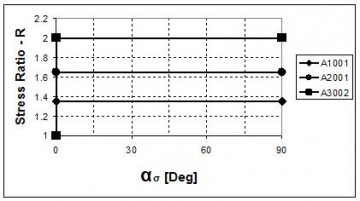

The HCT device is a valuble tool because it can apply a variety of loading paths, including controlled principal stress rotation in one plane; and has the ability to investigate the response of cross anisotropic materials.

The device has been used primarily for the study of the effects of principle stress rotation on the stress-strain response of cross-anisotropic soils.

Specimen size:

Inner Diameter = 6.9 cm, Outer Diameter = 10 cm, Height = 15 cm

Stress-Strain Application:

Stresses are applied by stepper motors and/or stepper motor driven water saturated pistons called digital volume-pressure controllers (DVPC’s). Stress is controlled by precision regulators and subsequent strain is controlled by the DVPC’s. Torsional shear is applied by means of four single acting pistons.

Independent control of four of the stresses yield independent control of the principal stresses (s1,s2,s3) and their direction (as) in one plane. DVPC’s enable predetermined volumes of water to be injected into or withdrawn out of the loading piston, and thus provide a convenient means of applying displacement controlled loading. Such a system does not suffer from the large compliance that is endemic in traditional motor driven gear systems.

Hollow Cylinder Torsional Device

Free Body Diagram

- Data acquisition using "National Instrument AT-MIO16x, 16-bit high-speed data acquisition card"

- 16 bit 3 channel D/A "Vextra Indexer" for DVPC controls.

- 15 bit equivalent 4 channel D/A card for stepper motor regulator controls.

- AT-MIO10x card with single ended A/D channels to read input from transducers.

- 16 Analog to Digital input channels:

- 9 A/D channels for transducers: Pressure Transdurs (3), DPT (2), LVDT (2), Load Cell (1), Torque Cell (1)

- DAQ is capable of gathering 6000 data sets per second.

- Gathered data is averaged over 60 readings to reduce electrical noise.

- Signal conditioning is done before feeding the signals into A/D cards.

| Transducer | Measurement/Control | Resolution |

| Load Cell | Vertical Stress | 0.2 kPa |

| Torque Cell | Torsional Shear Stress | 0.2 kPa |

| Pressure Transducers | Internal and External Pressure | 0.05 kPa |

| LVDT (Vertical) | Axial Strain | 0.001% |

| LVDT (Shear) | Shear Strain | 0.001% |

| DPT | Volumetric Strain | 0.001 kPA, (2mm^3) |

| Electro-Pneumatic Pressure Regulator | Apply and Control Shear Stress | 0.1 kPa |